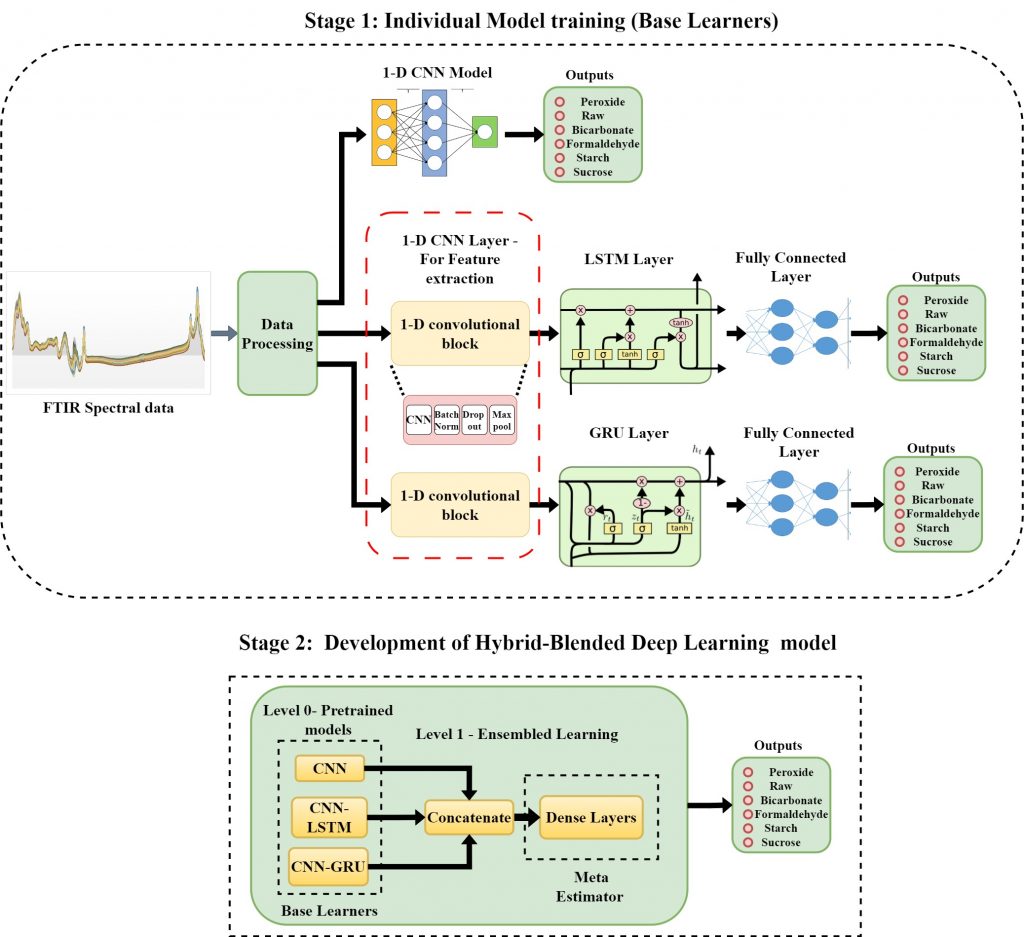

In the dairy industry, ensuring milk quality is vital, but traditional Machine Learning (ML) algorithms struggle with the complexity of milk spectral data and preprocessing challenges. Deep Learning (DL) offers promise but hasn’t been extensively applied to Milk Quality Analysis (MQA). To address this gap, a novel approach called Hybrid Blended Deep Learning (HyBDL) is proposed. HyBDL combines various DL architectures to improve accuracy and reduce errors in milk quality classification. Compared to traditional DL and Blended DL models, HyBDL demonstrated superior performance, achieving 98.03% accuracy and lower Mean Squared Error (MSE) scores.

It also consumes less power and energy while being faster to train than the traditional RNN models, making it suitable for real-world applications. What’s more, our research showcases the feasibility of training complex deep learning models on resource-constrained Edge devices, paving the way for real-time, on-edge milk quality predictions—a game-changer in dairy processing technology. We further validate these results on different machines to ensure the reproducibility of our developed DL model.

This research holds significant real-world implications. Consumers can feel more confident about the safety and quality of the milk they consume. Knowing that advanced AI technology is employed for rigorous quality monitoring reduces concerns about potential health risks associated with consuming adulterated or low-quality milk products.

Improved milk quality monitoring can enhance trust in dairy products and the dairy industry as a whole. Consumers rely on dairy products for their nutritional needs, and knowing that sophisticated technology is used to ensure quality can strengthen their trust in the industry’s integrity.

Efficient milk quality monitoring contributes to reducing environmental impacts by minimizing waste and optimizing production processes.

The development of Hybrid Blended Deep Learning (HyBDL) models for milk quality analysis showcases the application of cutting-edge technology in agriculture, highlighting the potential of AI to revolutionize various sectors beyond traditional tech domains.

The exploration of edge processing for training complex DL models opens up possibilities for implementing real-time milk quality monitoring in various settings, including small-scale dairy farms and processing plants. This could lead to improved accessibility and affordability of high-quality dairy products for consumers in different regions.

For future work, it will be interesting to see how the model performs when more adulterants are added to the multiclass classification problem. A larger dataset can be useful to further verify our results, and the use of other DL models which are useful for datasets with uncertainties, such as rough autoencoders, and deep temporal dictionary learning would be beneficial for performance comparison with our model. Using model compression techniques to lower the complexity of the model may also reduce energy consumption and will be applied in future work to reduce the memory footprint.

Future applications of this research might include implementing HyBDL models for real-time milk quality monitoring in dairy processing plants can improve efficiency and accuracy in quality control processes. This ensures that only high-quality milk is processed and packaged, enhancing product quality and reducing waste.

Dairy farms can utilize HyBDL models to monitor milk quality at various stages of production, from milking to storage. This allows farmers to identify and address potential quality issues promptly, ensuring the production of safe and nutritious milk products.

HyBDL models can assist dairy industry stakeholders in complying with food safety regulations and standards. By providing reliable and precise milk quality assessments, these models help ensure adherence to regulatory requirements and maintain consumer trust in dairy products.

HyBDL models can be integrated into precision livestock farming systems to monitor individual animal health and performance metrics related to milk production. This personalized approach enables farmers to optimize feeding, breeding, and management practices, ultimately improving milk quality and farm productivity.

The research is funded by Vistamilk-SFI Grant.

Link to the article: https://ieeexplore.ieee.org/document/10462585